Instrumentation

Instrumentation system – general information

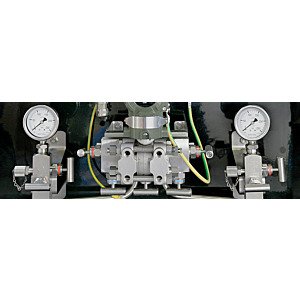

An instrumentation system is a pipe system conveying fluids or gases, used to measure, monitor and control the parameters of industrial processes in demanding technology and industry sectors. It makes a part of a broad field of control and measuring equipment and industrial process automation. The fluids and gases that are being processed, flow through process pipelines, are stored in tanks, mixed, undergo chemical reactions, change their parameters (pressure, temperature, flow rates, level and other variables). These parameters must be measured, monitored and controlled, which is accomplished through sensors, gauges, flow meters, valves and other elements connected by pipes to form a system. The instrumentation systems often operate in high pressure, vacuum, vibrations or high temperature conditions, conveying highly corrosive chemicals, working in adverse outer conditions. Another thing is that a false reading of process parameters or system breakdown may lead to catastrophic consequences. That is why, reliability is the most critical requirement for instrumentation systems. It applies to using superior quality, often very expensive materials, state-of-the-art precision machining technology and tight quality control.

There are numerous industries utilizing instrumentation systems, however they are the most common in the chemical industry, oil and gas, petrochemical industry, oil drilling, power industry, nuclear power plants, paper industry, pharmaceutical industry, production and transfer of high-pressure gases.